Belangrijkste kenmerken van verwarmingsschermen met aluminium reliëf

Feb 19,2025

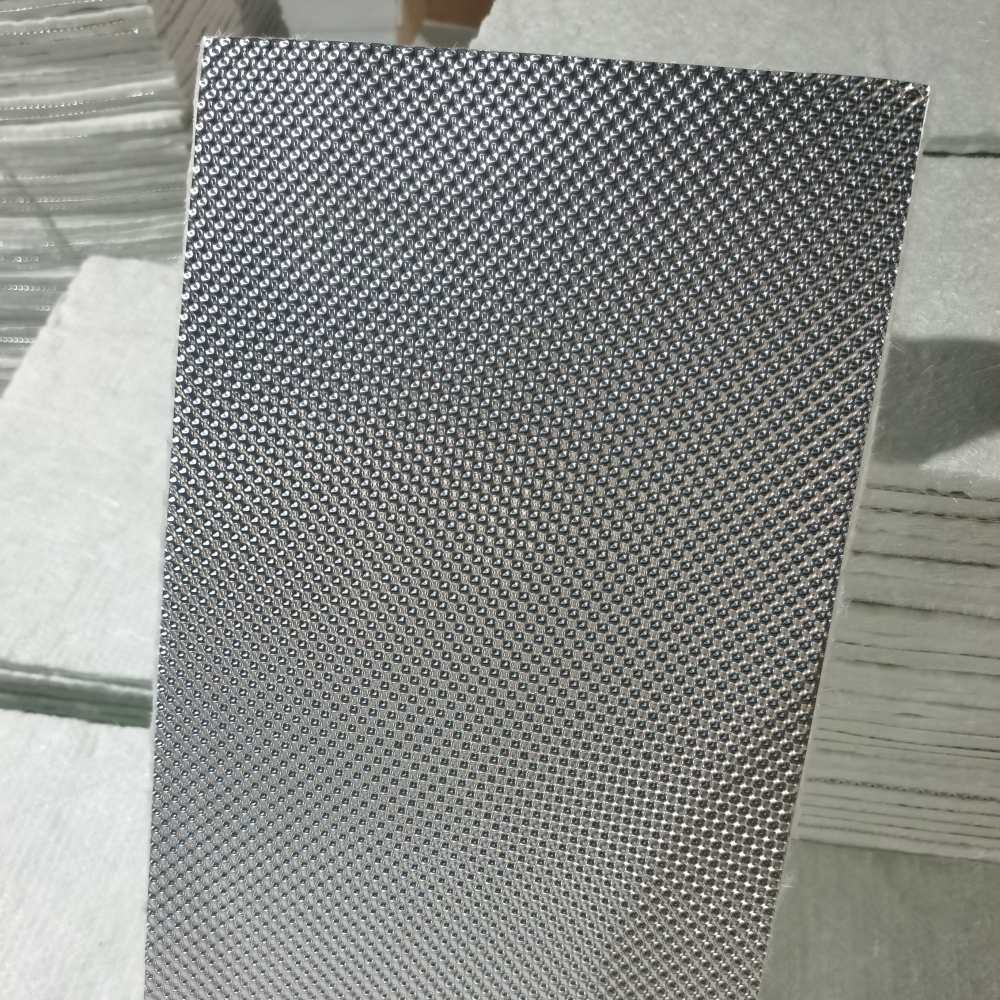

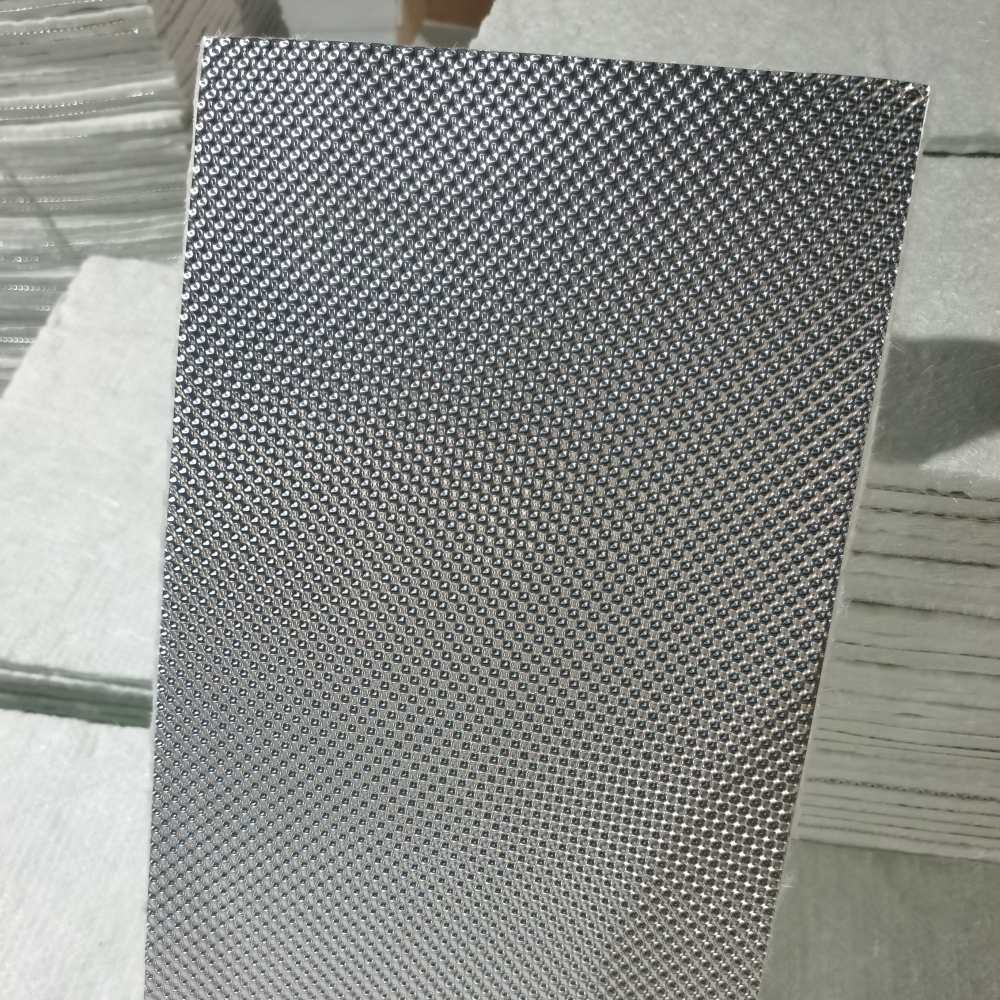

Aluminium reliëf warmteschilden worden ontworpen om superieure thermische bescherming te bieden in veeleisende omgevingen Met een uniek reliëfontwerp bieden deze warmteschermen een hoge duurzaamheid, flexibiliteit en weerstand tegen extreme temperaturen, waardoor ze een ideale oplossing zijn voor een breed scala aan toepassingen in verschillende industrieën

Belangrijkste kenmerken:

- Verbeterde thermische weerstand: De aluminium embossing creëert een barrière die effectief warmte weerspiegelt, waardoor schade aan gevoelige componenten wordt voorkomen en het risico op warmteoverdracht wordt verminderd

- Duurzame constructie: Gemaakt van hoogwaardig aluminium, deze warmteschermen zijn corrosiebestendig en zeer resistent tegen slijtage, waardoor langdurige prestaties worden gewaarborgd

- Aanpasbare vormen en maten: Beschikbaar in verschillende maten en vormen om te voldoen aan de specifieke behoeften van uw applicatie, inclusief aangepaste opties op maat van unieke vereisten

- Lichtgewicht en flexibel: Ondanks hun duurzaamheid zijn deze warmteschilden lichtgewicht en gemakkelijk te installeren, waardoor het totale gewicht wordt verminderd en de systeemefficiëntie wordt verbeterd

- Kosteneffectieve oplossing: Aluminium-reliëf is een kostenefficiënte methode voor het produceren van krachtige warmteschermen, het bieden van uitstekende prijs-kwaliteitverhouding zonder in te leveren op kwaliteit

Industrie -toepassingen:

Auto -industrie: Aluminium reliëf warmteschilden worden vaak gebruikt om kritieke motorcomponenten te beschermen tegen extreme warmte, waardoor de levensduur van uitlaatsystemen, turboladers en andere gevoelige onderdelen wordt gewaarborgd

- Voorbeeld: In uitlaatsystemen voor auto's voorkomen deze schilden dat overtollige warmte bedrading, slangen en andere materialen in de nabijheid van de uitlaat beschadigt

Ruimtevaartindustrie: Vliegtuigsystemen vereisen zeer efficiënte warmtebescherming vanwege de extreme temperaturen die tijdens de vlucht worden aangetroffen Deze warmteschermen worden gebruikt om motoren, turbines en uitlaatsystemen te beschermen

- Voorbeeld: In ruimtevaarttoepassingen zijn deze warmteschermen essentieel voor het beschermen van het vliegtuig ● S brandstofleidingen en elektrische systemen tegen motorwarmte

Industriële machines: In industrieën zoals constructie, mijnbouw en zware machines worden high-performance warmteschilden gebruikt om machines te beschermen tegen de hitte die wordt gegenereerd door motoren en uitlaten

- Voorbeeld: In mijntrucks helpen deze warmteschermen de motorcomponenten en hydraulische systemen te beschermen tegen schade veroorzaakt door de intense warmte die tijdens de activiteiten wordt gegenereerd

Mariene industrie: Boten en schepen die worden blootgesteld aan hoge temperaturen van motoren en uitlaatsystemen vertrouwen op aluminium reliëf warmteschilden om de veiligheid en betrouwbaarheid van ingebouwde systemen te waarborgen

- Voorbeeld: Mariene motoren gebruiken deze warmteschermen vaak om brandstofleidingen en koelsystemen te beschermen tegen oververhitting, waardoor een soepele werking wordt gewaarborgd

Stroomopwekking: Power-planten die afhankelijk zijn van hoogtemperatuurauto's zoals turbines en ketels gebruiken aluminium reliëfwarmteschilden om de systeemintegriteit te behouden en omringende apparatuur te beschermen tegen hitteschade

- Voorbeeld: In een energiecentrale worden deze schilden gebruikt om kabels en sensoren te beschermen tegen de intense warmte geproduceerd door turbines en stoomleidingen

Conclusie: Aluminium reliëf warmteschilden Bied veelzijdige, kosteneffectieve en duurzame thermische bescherming aan voor een breed scala aan toepassingen Of het nu gaat om automotive, ruimtevaart, industriële, mariene of stroomopwekking, deze warmteschermen bieden betrouwbare prestaties om de veiligheid en een lange levensduur van uw apparatuur te waarborgen.