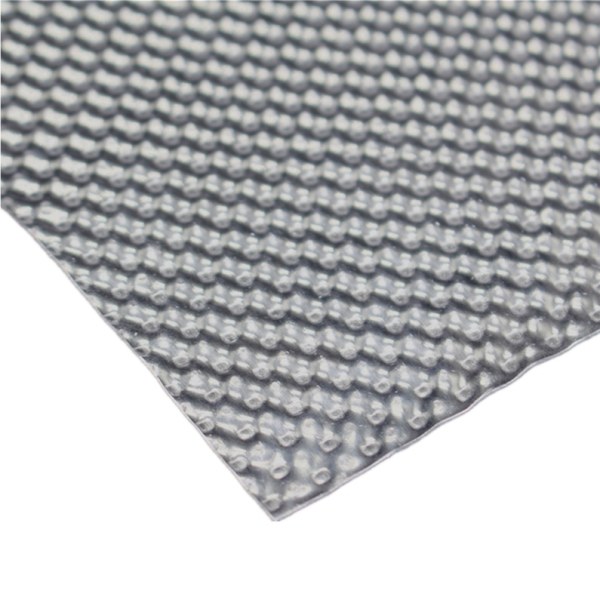

Een reliëf aluminium hitteschild Het is een warmtebeheersingscomponent vervaardigd uit aluminiumplaat die mechanisch in verhoogde patronen is geperst. Deze patronen zijn ontworpen om de thermische prestaties, structurele stabiliteit en luchtstroomregeling in omgevingen met hoge temperaturen te verbeteren.

In tegenstelling tot gladde aluminiumplaten, introduceren reliëfoppervlakken een gecontroleerde geometrie in het materiaal. Deze geometrie verhoogt de stijfheid en creëert micro-luchtbellen die warmteoverdracht helpen verminderen. Daarom worden reliëf-aluminium hitteschilden veelvuldig gebruikt in situaties waar gewichtsvermindering, warmtereflectie en duurzaamheid cruciaal zijn.

Van uitlaatsystemen tot industriële behuizingen: hittebestendige afschermingsoplossingen van reliëfaluminium zijn ontworpen om een balans te vinden tussen prestaties, kosten en betrouwbaarheid op lange termijn.

Reliëfpatronen verspreiden stralingswarmte en beperken directe warmtegeleiding. Het resultaat is een betere warmtereflectie en lagere oppervlaktetemperaturen op de beschermde componenten.

Door reliëf aan te brengen, worden aluminiumplaten versterkt zonder dat de dikte toeneemt. Hierdoor kunnen dunnere materialen een hogere stijfheid bereiken, waardoor reliëf aluminium hitteschilden ideaal zijn voor lichtgewicht systemen.

Aluminium is van nature bestand tegen oxidatie en corrosie. In combinatie met reliëfdruk behoudt het materiaal zijn vorm en eigenschappen, zelfs bij herhaalde temperatuurschommelingen.

In toepassingen met constante trillingen, zoals voertuigen en machines, bieden reliëf aluminium hitteschilden een betere weerstand tegen vermoeiing en resonantie dan vlakke platen.

De automobielsector is een van de grootste afnemers van hitteschilden van reliëfaluminium. Veelvoorkomende installatiegebieden zijn onder andere:

Uitlaatspruitstukken

Geluiddempers en katalysatoren

Turbocompressorsystemen

Bescherming tegen hitte onder het lichaam

Door warmte weg te reflecteren van gevoelige componenten, verbeteren reliëf aluminium hitteschilden de veiligheid, efficiëntie en levensduur van componenten.

In industriële omgevingen beschermen reliëf aluminium hitteschilden zowel apparatuur als personeel. Typische toepassingen zijn onder andere:

Hogetemperatuur leidingsystemen

Energieopwekkingsapparatuur

Ovens en thermische kamers

Mechanische behuizingen in de buurt van warmtebronnen

Huishoudelijke en commerciële apparaten vertrouwen op reliëf aluminium hitteschilden om veilige bedrijfstemperaturen te handhaven in compacte ruimtes, met name in ovens, verwarmingstoestellen en HVAC-systemen.

Verschillende reliëfpatronen dienen verschillende technische doeleinden. De keuze voor het juiste patroon hangt af van thermische, mechanische en ontwerpeisen.

| Reliëfpatroon | Functioneel voordeel |

|---|---|

| Diamantpatroon | Evenwichtige sterkte en warmtereflectie |

| Golfpatroon | Verbeterde luchtstroom en trillingsbestendigheid |

| Honingraatpatroon | Maximale stijfheid met minimaal gewicht |

| Aangepaste geometrie | Toepassingsspecifieke optimalisatie |

Elk patroon beïnvloedt de manier waarop het reliëf aluminium hitteschild reageert op warmte, luchtstroom en mechanische spanning.

Een hitteschild van reliëfaluminium kan, afhankelijk van de prestatie-eisen, worden vervaardigd uit verschillende aluminiumlegeringen.

3003 Aluminium: Uitstekende vormbaarheid en thermische prestaties.

5052 Aluminium: Hogere sterkte en corrosiebestendigheid

8011 Aluminium: Kosteneffectief voor toepassingen met grote volumes.

0,3 mm – Lichtgewicht en flexibel

0,6 mm – Standaard voor industrieel en automobielgebruik

1,0 mm en hoger – Zware thermische beveiliging

Door de juiste legering en dikte te kiezen, zorgt u ervoor dat het reliëf aluminium hitteschild betrouwbaar presteert onder bedrijfsomstandigheden.

De productie van een reliëf aluminium hitteschild omvat verschillende gecontroleerde stappen:

Bladvoorbereiding – Aluminiumrollen of -platen worden gereinigd en voorbereid.

Reliëfproces – Precisierollen creëren uniforme reliëfpatronen

Snijden en vormen – CNC-snijden, -stempelen of -buigen geeft het onderdeel vorm.

Oppervlakteverbetering – Optionele coatings of reflecterende lagen kunnen worden toegevoegd.

Inspectie en testen – Dimensionale en visuele kwaliteitscontroles

Dit proces garandeert consistentie, nauwkeurigheid van de prestaties en schaalbaarheid voor massaproductie.

Een goed ontworpen, reliëf aluminium hitteschild biedt consistente thermische bescherming over een breed temperatuurbereik.

Weerkaatst een groot percentage van de stralingswarmte.

Behoudt stabiliteit bij herhaaldelijk verwarmen en afkoelen.

Bestand tegen scheuren, kromtrekken en oppervlakteafbraak.

In veel toepassingen functioneren reliëf aluminium hitteschilden effectief bij temperaturen tot 500-600 °C, afhankelijk van de legeringskeuze en de installatiemethode.

Standaardproducten voldoen mogelijk niet altijd aan de specifieke eisen van een project. Op maat gemaakte, reliëfbedrukte aluminium hitteschilden stellen ingenieurs in staat de prestaties te optimaliseren voor unieke omstandigheden.

Op maat gemaakte reliëfpatronen

Meerlaagse constructies

Geïntegreerde isolatiematerialen

Complexe geometrieën en montagemogelijkheden

Ontwerpen op maat zijn met name waardevol voor OEM's en systeemintegratoren die op zoek zijn naar een verbeterde thermische efficiëntie en compacte lay-outs.

Bij de keuze voor een hitteschild van reliëfaluminium moet u rekening houden met de volgende factoren:

Begrijp het temperatuurbereik, de warmterichting en de blootstellingsduur.

Houd rekening met trillingen, vocht, chemicaliën en ruimtebeperkingen.

De automobiel- en industriële sector vereisen vaak naleving van specifieke normen.

Een betrouwbare leverancier moet materiaalkennis, consistente kwaliteitscontrole en ondersteuning bij maatwerk bieden.

Door reliëf aan te brengen, wordt de stijfheid verbeterd, de warmteoverdracht verminderd en de trillingsbestendigheid verhoogd zonder het gewicht te verhogen.

In veel toepassingen wel. De duurzaamheid van aluminium maakt langdurig gebruik mogelijk, mits het niet fysiek beschadigd raakt.

Ja. Meerlaagse constructies met een isolerende achterkant zijn gebruikelijk in omgevingen met extreme hitte.

Ja. De corrosiebestendigheid van aluminium maakt ze geschikt voor gebruik buitenshuis en in zware omstandigheden.

De dikte is afhankelijk van de temperatuur waaraan het wordt blootgesteld, de mechanische belasting en de gewichtsbeperkingen.

Absoluut. Reliëfdruk is zeer geschikt voor zowel kleine series als grote productievolumes.

Een reliëf aluminium hitteschild Het is een beproefde oplossing voor warmtebeheer in automobiel-, industriële en commerciële toepassingen. De combinatie van thermische efficiëntie, lichtgewicht sterkte en ontwerpflexibiliteit maakt het een uitstekende keuze voor moderne uitdagingen op het gebied van thermisch beheer.

Door het juiste materiaal, reliëfpatroon en leverancier te kiezen, kunnen bedrijven betrouwbare hittebescherming realiseren en tegelijkertijd de prestaties en kosten optimaliseren. Of het nu gaat om standaardmodellen of maatwerk, aluminium hitteschilden met reliëf spelen een essentiële rol bij het verbeteren van de veiligheid, efficiëntie en levensduur van producten.