De auto- en ruimtevaartindustrie is voortdurend op zoek naar verbeteringen in materialen om de prestaties, veiligheid en efficiëntie te verbeteren. Een cruciaal aandachtsgebied is het thermisch beheer, vooral met betrekking tot uitlaatsystemen. Uitlaathitteschilden zijn essentiële componenten die zijn ontworpen om gevoelige gebieden te beschermen tegen overmatige hitte en de algehele systeemefficiëntie te verbeteren. Dit document biedt een diepgaande blik op verschillende materialen voor uitlaathitteschilden, waaronder uitlaatwarmtedekens, wikkels, mouwen en meer, samen met hun toepassingen en voordelen.

Warmtewikkelingen voor uitlaatgassen behoren tot de meest gebruikte oplossingen voor thermisch beheer. Ze zijn ontworpen om de uitlaatpijpen af te dekken, waardoor de stralingswarmte wordt verminderd en de uitlaatgassnelheid wordt verbeterd.

Glasvezel: Glasvezelwikkels zijn populair vanwege hun hoge temperatuurbestendigheid en kosteneffectiviteit. Ze zijn bestand tegen temperaturen tot 650 °C (1200 °F) en zijn geschikt voor de meeste automobieltoepassingen.

Titanium: Titanium wraps zijn gemaakt van verpulverd vulkanisch gesteente en kunnen hogere temperaturen verdragen, tot 982 °C (1800 °F). Ze zijn duurzamer en bieden superieure prestaties bij hoogwaardige en racetoepassingen.

Keramisch: keramische omhulsels bieden uitstekende thermische isolatie en zijn bestand tegen temperaturen tot 1093 °C (2000 °F). Ze zijn ideaal voor extreme omstandigheden waarbij maximale hittebescherming vereist is.

Uitlaathulzen bieden flexibele en robuuste bescherming voor uitlaatpijpen en componenten. Ze zijn verkrijgbaar in verschillende materialen, elk geschikt voor specifieke toepassingen.

Uitlaatmof met siliconencoating: Deze hoezen combineren de hoge temperatuurbestendigheid van glasvezel met de duurzaamheid van siliconen, waardoor ze ideaal zijn voor het beschermen van draden en slangen in de buurt van uitlaatsystemen.

Uitlaatmof van glasvezel: Deze hoezen bieden uitstekende thermische isolatie en flexibiliteit, waardoor ze geschikt zijn voor een breed scala aan automobiel- en industriële toepassingen.

Basalt-uitlaathuls: basalthulzen zijn gemaakt van vulkanisch gesteentevezels en bieden superieure hittebestendigheid en duurzaamheid, en zijn bestand tegen continue blootstelling aan temperaturen tot 760 °C (1400 °F).

Uitlaatwarmtedekens zijn op maat ontworpen afdekkingen die over specifieke componenten passen, zoals turbocompressors of spruitstukken, om de warmte effectief vast te houden en te beheren.

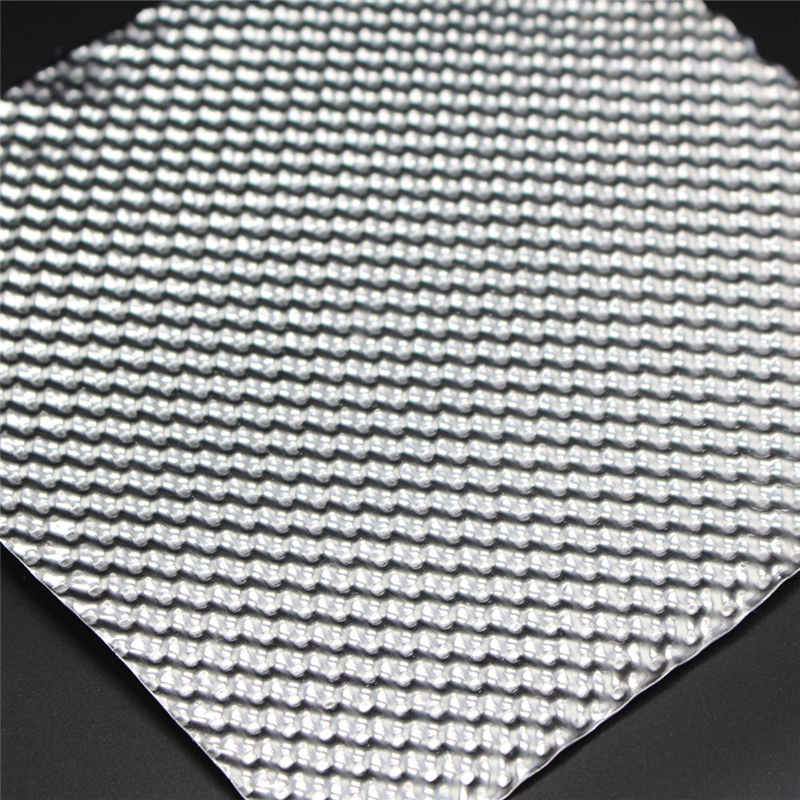

Aluminium hitteschilden met reliëf zijn licht van gewicht en bieden uitstekende warmtereflectie-eigenschappen. Ze worden vaak gebruikt in automobiel- en industriële toepassingen waar gewichtsvermindering cruciaal is.

Toepassingen: Aluminium schilden met reliëf worden gebruikt in motorcompartimenten, bodembescherming en afscherming van uitlaatsystemen.

Voordelen: Deze schilden bieden weerstand tegen hoge temperaturen, corrosiebestendigheid en installatiegemak.

Roestvrijstalen hitteschilden bieden verbeterde duurzaamheid en corrosiebestendigheid, waardoor ze geschikt zijn voor zware omgevingen en toepassingen bij hoge temperaturen.

Toepassingen: Veel gebruikt in uitlaatsystemen, turbocompressoren en industriële machines.

Voordelen: Ze bieden langdurige bescherming, uitstekend thermisch beheer en mechanische sterkte.

Bij krachtige voertuigen is het beheersen van de uitlaatwarmte van cruciaal belang om optimale motorprestaties en een lange levensduur te garanderen. Een raceteam gebruikte bijvoorbeeld titanium uitlaatwraps op hun turbomotoren, wat resulteerde in lagere temperaturen onder de motorkap en een verbeterde uitlaatgassnelheid. Dit leidde tot meer pk's en betere algehele voertuigprestaties.

In de lucht- en ruimtevaartindustrie is thermisch beheer van cruciaal belang vanwege de extreme omstandigheden tijdens de vlucht. Basalt-uitlaathulzen werden in een recent ruimtevaartproject gebruikt om kritische componenten tegen hoge temperaturen te beschermen, waardoor de betrouwbaarheid en veiligheid van het vliegtuig werd gegarandeerd.

Uitlaathitteschildenzijn essentiële componenten in de moderne auto- en ruimtevaarttechniek. De materiaalkeuze (glasvezel, titanium, keramiek, siliconencoating of basalt) hangt af van de specifieke toepassing en prestatie-eisen. Geavanceerde oplossingen zoals aluminium en roestvrijstalen hitteschilden bieden extra voordelen, waaronder gewichtsvermindering en verbeterde duurzaamheid. Door de juiste materialen te selecteren, kunnen ingenieurs de warmte effectief beheren, de prestaties verbeteren en de levensduur van kritische componenten garanderen.